Welcome to Tru-Knit

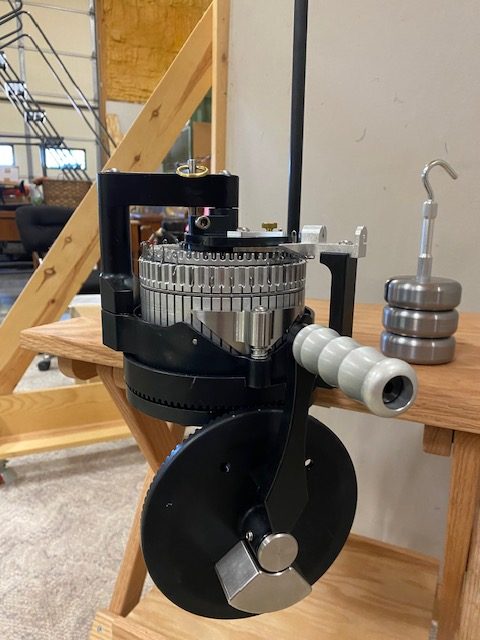

Home of the Tru-Knit Circular Knitting Machine by Jamie Mayfield.

Learn about the Tru-Knit Circular Knitting Machine features and prices here on the Tru-Knit Product Page.

Watch our Tru-Knit How-To Videos for tips, tricks, and inspiration.

Our Shop is live! Visit our Shop.

Check out our interactive Tru-Knit Owner’s Map! 🌎 It’s downright amazing to see just how far and wide folks are cranking on their Tru-Knits. And don’t miss the special song we put together to celebrate this big ol’ worldwide knitting family— see where in the world people are makin’ socks with Tru-Knit!

Visit our Tru-Knit User Guides for User Manuals and Tru-Knit Circular Knitting Machine documentation.

Our Shop is live! Visit our Shop.

Please note we have machines in stock! Ready to build, test and ship! We invest in a lot of inventory so you don’t have to wait for a machine. This is very important to us. Once you make the decision, it’s senseless to have to wait…so we have enough inventory to meet the demand!

Payment Info: You can pay by check, credit card or paypal. If your browser gives you a fit, choose the Reserve Pay Later option, we will contact you to see how you would like to pay. If you choose to pay by check, we will have your machine ready to ship when your check arrives (I strongly suggest sending it with a tracking number). If you choose to pay with a credit card or paypal, then we will have your machine ready to ship on the second business day.

Read what our customers are saying about their Tru-Knit Circular Knitting machine:

Joanne Talbott

The customer service by Jamie and Jeff at Tru-knit is incredible. I received my machine in one week from the day I ordered it. Everything is as they say it will be and they are always within a day of answering any questions or a phone call away. So far it has been a

wonderful experience buying a Tru-Knit sock machine.

Kim Rusnak

I learned how to knit 6 months ago. Haven’t attempted anything other than blankets, hats and scarves. Wanted to try socks and kept getting intimidated. A friend told me that she was researching circular sock machines and was going to a crank-in because there were three different machines she was looking to try. We went and played with an Erlbacher and a Tru-Knit at this crank-in. Fell in love with the tru-Knit. The silver bullet and the way it opens the needles as they are turning around the cylinder is what sold me. On the way home, I had the courage to purchase a machine, but was reluctant to spent any significant amount of money. So I purchased a 3-D printed machine. After finding out that it would take 5-6 weeks to receive, I purchased the Tru-Knit. TheTru-Knit was shipped out the same day I placed my order (Friday), and was in my hands on Monday. I spent two weeks learning how to work the machine and texted Jamie several times with questions. I knew immediately that the customer service I was receiving was extremely rare. Within my first month, I had made 6 pairs of socks. Five weeks later, I received my 3-D printed machine and spent almost a month trying to make a single sock on the machine There was no support, no videos or instruction manual on how to work the machine. When I reached out to the seller to ask questions about how to work the machine, my emails were ignored. The 3-D machine felt like a flimsy machine that would break within 3 months. I returned the 3-d printed machine and never looked back. . The tru-knit is very stable, is easy to use, does not hurt your hand to crank, has exceptional instructions and videos and has amazing customer service. It is super easy to adjust tension, switch crank handles, and switch cylinders.

I love this machine.

Jill Courtright

Great customer service!

Maryann B

Love the sound, feel and function of this American made sock knitting machine. Well worth the dollars to make long lasting and well fitting socks for family and for sale.

Rochelle Yankwitt

The Tru-knit is a pleasure to use and a brilliant piece of machinery. Everything about the machine is very smooth and works as intended. The customer support is great. I would definitely buy this product again and am very happy with it.

Anne Marie Propst

Bought a D&B and couldn’t get a sock made to save my life. Ordered Tru-Knit and what a difference in the learning curve. I still have a lot to learn but now I think a sock might actually be in my future!

jsschnc

Hats off to Jamie, Jenny and her husband for offering this table which can be used for a lot more than my CSM. I was impressed with:

1) How well it is crafted. The oak is clear and without checks or blemishes in the wood. All pieces have been milled, shaped, sanded, including rounding over sharp edges. This is legitimately a furniture quality piece. My opinion on this is qualified. I built all the Craftsman style furniture in my house so I have deep appreciation for high quality woodworking.

2) How well it was packed. It took me almost 15 minutes to get it out of the box and unwrapped. This is not a complaint. This table was in no danger of being damaged during shipping. That’s a good thing. Nothing worse than really looking forward to getting something delivered and opening it only to find it’s broken or marred.

As they say in the online shopping world, “Buy with confidence! “

Caroline Lourie

Easy order process and transparent pricing. Quick delivery and great communication. INCREDIBLY well designed packaging, machine and all accessories came in two boxes without any damage, loss or issue.

Very easy and quick to set up, and able to start cranking immediately. Split yarn carrier is a game changer for me, although it has taken a little while to get used to where the yarn is caught by the needle to avoid holes when I change e.g. waste to project yarn.

The machine is very well made and finished, and a dream to work with. My only criticism of the set up is the needles, which are a bit fragile compared to my experiences with those on a vintage Imperia.

Really delighted with my purchase, and so sweet to see my little outlier dot on the customer map – any UK folks want to reach out to chat to me about the machine, you can find me on the Tru Knit Facebook page or Facebook Vintage Krankers page, we might even get a chance to meet up at a UK crank in, I would be more than happy to demo.

Finally, thanks to Jamie and the team, great piece of engineering and outstanding customer service – even after purchase, so much support through the tutorial videos/sock TV and the social media platforms.

Cindy VanKamme.

I love my Tru-knit! It knits like a dream. I hardly ever get dropped stitches. Ribbing is easy on this machine. Customer service cant be beat. Questions are answered promptly. Not one moment of regret with getting this machine!

Meg Bateman

Seriously the best experience I’ve ever had when making a large purchase! Jamie and Jeff are amazing and their Tru-Knit machine definitely sets a very high bar for others to *try* to reach. Worth every penny.

Andrea Monfried

I love my Tru-Knit. It is obvious that expert knowledge went into designing every inch of this machine – it purrs like a finely tuned car as the cylinder rotates. All of the materials are high-quality – it will last for decades or even longer. It’s especially great that the machine comes with all of the necessary accessories – cast-on bonnet, extra needles, oil, etc.

Dina Mccarthy

I have never been so happy in my life! I cannot wait to get home from work to get up in the morning any minute. I have to work on this machine. It is a dream. And Jamie is very helpful and kind. Don’t hesitate. Don’t even think twice just go ahead and go for it. You won’t be sorry!

Melissa Jones

I am in love with Tru-Knit. I previously owned another brand of csm and never could get the hang of it. I’ve had my Tru-Knit for about a year and straight out of the box it’s been a joy to work with. Jamie’s help and videos have been an added bonus !

Sharon

I am in Australia and I received my Tru-Knit sock machine within a week! It is the Rolls Royce of csm’s so much thought has been put into the design of this machine. All the frustrating quirks of csm’s have been eliminated and you will be cranking socks within your first week even if you have no previous sock machine experience, just follow the excellent written manual showing you all the steps. I had previously owned a sock machine but had never progressed from cranking tubes, I am now knitting socks daily, I’m addicted and finally my huge sock stash is being used and my family are loving their new socks. Highly recommend this company for excellent service and ongoing support.

Jean Trumpy

Phenomonal customer service!

Emma Anderson

This is a phenomenal machine! Customer service (aka ask a question) is great! And it is really pretty! (And simple to setup!)

Rebel Mead

The Tru-Knit is a spectacular machine! Knits like a dream and makes doing ribbing a breeze! The customer service is top-notch. Jeff personally called me after I placed my order to ask if I wanted a specific font for the personal engraving of the tools. And Jamie is always quick to reply to any questions you may have. Thank you so much for making this wonderful machine available. 10/10 recommend the Tru-Knit machine!

Jaci Zahringer

I have wanted a CSM for years since I was a teenager and saw someone demonstrating on one. I LOVE my Tru-Knit! My only other experience is on an older NZAK and I didn’t try ribbing on that. Right out of the box the Tru-Knit worked perfectly. Likely because Jamie set it all up and made a sock to fit me. She also left directions to make the second sock. I got it on the first try, ribbing and all, just 24 hours after receiving my CSM. I have made 3 more pairs in the last week.

The design is smooth and seems very well thought out, using Allen wrenches to adjust everything that I can see, no screws to strip. It is also much quieter than I expected. I have watched so many videos with other brands and some sound quite loud and clicky. My Tru-Knit sounds so pleasant to me.

Customer service is phenomenal! Jamie emailed me right away communicating details and asking my foot size. I am so excited to be diving into cranking!!

cindy helen brandt

I Love My Tru-Knit! I called and talked to Jamie to order it. The process was as fast as it could be- I think it took like 6 or 7 days, and most of that time was waiting for my check to get through the mail. The machine arrived safe and sound, so well packaged, and exactly as ordered. Jamie provides help whenever you need it. The silver bullet works! Just like it’s advertised, you can watch it open the latches as it goes around. And now I’m happily cranking out socks of all sizes and shapes! Just love it, can’t say enough good things.

Kim Kieffer

A Flawless Sock Machine & Incredible Support from Jamie!

I am absolutely in love with my Tru-Knit sock machine! The **quality is exceptional**—it’s built to perfection, runs **smoother than any machine I’ve used before**, and arrived **securely packaged** to prevent any shipping damage. Compared to my old machine, this one is **easier to use, more consistent, and far more enjoyable** to work with.

But the real standout is the **unmatched customer service from Jamie**. Every time I’ve had a question, Jamie has been **patient, knowledgeable, and quick to help**—making the entire experience stress-free. It’s rare to find such **personalized, top-tier support**, and it truly makes all the difference.

If you’re on the fence about getting a Tru-Knit machine, **don’t hesitate**. This is hands-down the best sock machine I’ve owned, and Jamie’s outstanding assistance ensures you’ll never feel stuck. **10/10—highly recommend!**

Denise Edmister

Love, love, love my TruKnit! The machine is the easiest to use for a beginner. I produced a sock with the first use.

Sue Moore

Great customer service.

Dawn Wolfcale

I love my Tru-Knit! The customer service provided by Jamie and Jeff has been quick and thorough. They respond to questions and patiently will working with you to solve problems and makes sure you understand the process. I could not be happier with my purchase!

Shawn Stoner

Incredible machine! Ready to go out of the box and customer service is beyond great!

Cindy Hamming

The Tru-Knit is an amazing machine and the support from the start has been 5 star. I highly recommend the Tru-Knit to anyone considering a CSM.

Shelley Ellerkamp

One of the best purchases I’ve ever made. Everything I needed came with my initial purchase and it knits like a dream right out of the box. There are lots of videos to help with every little thing. Jamie’s customer service is above and beyond!

Julie Hallock

Very easy to work with.

Emma Anderson

Oh my!!! I just received my Tru-Knit this past weekend. I am not a very experienced cranker but this machine is knocking my socks off! 🙂 Jamie really has thought of SO MUCH in pulling this together.

The manuals – are great! – and the font size is READABLE! Thank you thank you thank you!

The online videos – short and sweet – very understandable! (and Ranger is a cutie!)

CSMs are in general pretty daunting at first glance – but Jamie’s machine, manuals, videos – and customer service take so much of the fear away. Yes, I know I will make mistakes – but super excited to crank-away!

Marie-Christine Vallet

Likes

Manuals: Clear set up instructions and patterns easy to follow.

Machine: Ready to knit out of the box.

Silent and lightweight ( these are the main reasons that made me decide to buy this one over the others)

Allen keys are provide, this is great as I think on this side of the pond they are not the same size.

Silver bullet : no dropped stitches, makes making heels and toes a breeze.

Clamping : easy to do on any surface.

Cylinder markings: Lines are really nice to remember what you doing to your stitches.

Marking of the size on the cylinders and dials are really nice and easy to see.

Super cute set up bonnets provided with the machine .

Ease of use: The machine is ready and set to go without any adjustments. This makes it every nice for a beginner to get started without any prior CSM experience. The ribber can be adjusted on the fly in less than a minute.

Shipping: Super fast. Being informed that Jamie sent packages on Mondays to avoid that they get stuck somewhere in the weekend was really helpful to me as I knew not to be too impatient, that said it was super fast.

Customer service : Very helpful, even before I bought the machine, and super fast to answer my beginner’s questions. Jamie helped me find someone who would let me see the machine in person so I could make my choice. She helped me choose the cylinders that are suited to my needs. And she is always there to answer my questions.

Things I don’t like as much

Yarn counter: Not my favorite, but it is silent and as no moving parts. From experience with another identical counter I know the battery last for a very long time even if you forget to turn it off. Having to move it every time I have to change the cylinder is not great, but still very easy and straightforward.

Handle: For my hands I would have benefited from an extra grove so about 2cm, that said it is still is very comfortable to crank for long hours

Over all super happy with the machine and I am happily surprised I could get it going in so little time ( was able to make my first ribbed sock in a very short time despite having no prior experience on a CSM followed by a half pitch hats soon after). I still have a lot to learn, but I am looking forward to it. The more I use it the more things I like bout it.

Heather Gibson

I absolutely love my Tru Knit! The attention to detail in not only the creation of this machine, but also in the accessories and manual is outstanding. I have been having so much fun creating handknit socks for everyone in my family and can’t wait to make more! Everyone is getting knit socks for Christmas! Jamie Mayfield clearly knows what she’s doing! I have had my machine for almost a month now and I’m already using the ribber with no trouble! I’ve surprised myself!

I also want to take a minute to talk about the customer support. They were so great at communicating and answering all my questions. My machine arrived quickly and was immaculately packed. Set up was guided by videos and the manual and was a breeze. I honestly can’t say enough good things!

If you do buy this machine, which obviously I recommend, do yourself a favour and check out Sock Tv as well. The videos are excellent and I’ve learned so much! I can’t wait to keep practicing and keep refining my skills!

Jean Van Dyke

I love my Tru-Knit. It solves so many frustrating issues with previous machines I’ve used. In fact, I am planning on selling all of my other machines as I only use the Tru-Knit now. I rarely have to make any adjustments on this machine. The silver bullet is amazing at preventing dropped stitches by opening closed latches. It’s great for traveling to Crank-ins as it is light weight and easy to take down and set up. I can crank in the same room that my husband is watching TV because it is so quiet. Shopping for Tru-Knit supplies is great. I recently ordered an additional cylinder and ribber dial and had it within a week.

Kathy Sturtevant

I absolutely love my TruKnit!!! There are less dropped stitches, and using the ribber is so easy. The short and long slots in the ribber make it easier to know where to insert your needles, and there is less of a chance of making a mistake. This machine only weighs 8 lbs, so taking it to retreats or on vacation is a no brainer. Your back will thank you. This is a very well thought out machine, and I am a fan!!!

Happy Knitting

I have been a hand knitter most of my life, but a friend of mine got me interested in CSM machines when she let me play with her Erlbacher, and once I caught the bug I started researching and saving up because I knew I just had to have a machine of my own!

This machine is AMAZING!! I chose it because it’s supposed to be one of the more user friendly machines out there according to my research, and I do feel that it certainly is although I don’t have experience with many brands so I can’t do much personal comparing, but I can say that I LOVE it :)! and Jamie is incredible, she helped me to choose the specs for what I would need because I was a complete beginner starting out so wasn’t sure even which cylinders to start with!….

There is definitely a learning curve to creating with CSM machines, but with Jamie’s youtube channel and so many other useful videos and other reference files out there, learning has actually been surprisingly pain free and sooo much fun!

And now after only a couple of months of having the machine I have made more than 70 items (some with more success than others of course teehee), but I’m having a blast learning and creating!!

(I still haven’t braved the ribber yet, but I’m told the TrueKnit ribber is much easier to use than other machines so that’s my next thing that I plan to tackle in the new year and I can’t wait to give it a go :))… but even without the ribber I have made all kinds of socks, and gloves, plus by adding some spacers I have created more than 30 adult sized toques too, so I managed to make Christmas gifts that I’m happy with for all of my family members this year in a short amount of time!!

Such an incredible piece of machinery, and incredibly well designed, the more I use it the more I’m learning how it functions and how to make it accomplish what I want to do.

I would highly recommend the TrueKnit Machine to anyone who’s wanting to buy a new CSM machine, all I can say is it’s AWESOME!

I haven’t had this much fun learning something new since I was a kid!! I did hummm and hawww about the price in the beginning, wondering if it would actually end up being something I used long term, but I can honestly say that for me at least it’s the best $$ I have spent in a very long time, and I feel like a kid in a candy store every time I get to play with my new toy!

Thank you so much Jamie for making such an incredible machine!

~Kristin

Sharon Dreifuss

I can not say enough good things about the entire Tru-Knit experience. From the ease of use of this machine through to the incredible in the moment support thats available to you from the creator of the machine Jamie Mayfield herself. This has all been and continues to be a complete joy.

Lissa Mosley

I love my Tru-Knit. It’s not fussy or temperamental; it just works smoothly and reliably. Jamie is helpful and accessible. I’m delighted!

JENNIFER MALIA

I Absolutely Positively Unabashedly LOVE my tru-knit!! I had a different brand that I always had difficulty ribbing with, even with expert advice. The Tru- knit I am ribbing like a pro – Jamie is ALWAYS available it’s incredible to have such one on one with the creator! Anyone looking to buy a CSM please buy a Tru-knit you’ll love, the silver bullet, and ribber primed and ready to!

Jane Clark

I purchased my Tru-Knit nearly 1 year ago. I waited to post my review so that I could really put it through the paces. It doesn’t disappoint! It is the small things that matter most. The Silver Bullet for stitches not dropping, the long and short slots on the ribber dial just to mention a few. The customer service is top notch! Make the investment, you won’t be sorry! I sure am glad I did!

Now more time has passed and I am still thrilled with this product. I would highly recommend this machine! If there were 10 stars, I would give it a 10!

Mary Cunningham

Oh my goodness! The Tru-Knit is all that it is cracked up to be. I love the dependablity of the machine and materials. It is so nice not to have to remove the Ribber Guide when changing cylinders. So helpful to have a great visual regarding tension on the cylinder. So comforting to have a lock pin to keep curious fingers from cranking behind my back! So many more advantages to this machine! I could go on and on…..

As for customer service? Jamie rocks!! She responds quickly and ready to chat in person if needed! 5 STARS!!!

Deborah Cohen

I’ve knitted on several machines: Gearhart, Speedster, NZAK, Chambourd. The Tru-Knit has hands down been the best experience. I wish it’d been around when I was a beginner! Highly recommended.

Karrie_FreckledWhimsy

I have owned several different machines, which are all great machines, but the Tru-Knit is my favorite to knit on. The others that I own have not been in use since I received my Tru-Knit. I love it so much I actually own two. One for home and one for my business! Set up is easy and it’s already calibrated. It ribs like a dream! I would HIGHLY recommend this machine to anyone looking! And you likely won’t have to wait months to get yours which is a huge plus too! Thanks Jamie and team for all of your hard work!

Dawn Copeland

I owned 3 antique machine prior to purchase. They all have their quirks due to years of service, improper storage, and parts being separated over time. The Tru-Knit is perfect out of the box. Everything you can need or want to start is included. There are no hidden add-ons. I made my first fully ribbed sock after years of trying and failing. Customer support is immaculate.

Heddi Craft

I started using a Tru-Knit a week ago, and I just have to say- WOW! Jamie has really created a machine solves many of the problems of older machines. If you are new to cranking socks, this is the machine for you!

First of all, it can be completely assembled using four tiny hex keys that come with it (made in the USA). No fumbling around with wrenches and screwdrivers of various sizes. The assembly is straightforward and easy to do following the start up guide. The machine is light enough that I never worried about dropping it.

Second, the settings are set up so that you can use the machine straight out of the box with the provided yarn. There’s even a completed sock for you to copy so that you have a pair in no time! There’s lots of little touches, like markings on the cylinder that allow you to see your tension setting easily, a counterbalance built in to the handle, the Silver Bullet yarn carrier that will open closed latches if set correctly, and a digital row counter.

Finally, the ribber is a dream to use. The cylinder lever easily allows you to adjust the ribber, the timing is set perfectly when the machine arrives, and the ribbing comes out beautifully! There are lots of little touches on the ribber that allow you to create a ribber selvedge with precision.

There are lots of great short videos on the website will help you get started. I’m an experienced sock machine user and this machine has been a joy to work with– it would make a great first machine.

Brandi Fogel

The Tru-Knit is an amazing circular sock machine! The machining is top-notch and it is very light, making it easy to transport. There are so many user-friendly features that it would be impossible to list them all. Perhaps the most important is that as a Tru-Knit owner, you receive top-notch customer service from Jamie and her husband Jeff. They really care about our CSM community and the care taken in designing this machine and helping us master this craft is beyond measure.

WJW

I have had my Tru-knit CSM for a few weeks and I set out to challenge it the very first time I knitted on it with a short tab no-show sock on it.

I wanted to challenge the Tru-Knit as I have a different brand of CSM that I have never been able to knit on without dropping stitches.

Yes, I am a newbie CSM knitter. I received my first machine this spring. So after knitting on the first CSM, I have the technical knowledge for how to knit various sock anatomy but never was able to do short rows without dropping stitches no matter how slow or careful I was being.

I learned about the Tru-Knit by word of mouth. It has great reviews and many pleased enthusiastic owners, so I decided to purchase it even though I had a new machine already.

It arrived shortly before the July holidays and I set it up to see what it could do. I knitted the short sock at a faster pace than I would normally, not even being cautious at the corners of the short rows.

I finished that sock without a single dropped stitch! I sat back after finishing and just stared at it. This machine is amazing.

Finally, when I was having a problem that I needed assistance, I contacted them on a weekend when they were attending a Crank-In. I received several calls with advice until I found that a malfunctioning needle needed replaced. Customer service and support is great and IS there when you need it.

Last but not least, I signed up for sock TV and I love it. At this time there are over 360 videos that I can play over and over to enjoy and learn CSM skills. Every video is a lesson with new skills and includes care of the machines. There is usually a new video every week.

I am so glad I bought a Tru-Knit.

Adriane Weatherby

This is such a smooth running, beautiful machine! It ribs without complaint and Jamie and her team have added so many genius changes…. I’m really enjoying getting to know this new machine!

-Adriane Weatherby of Tundra Toes Knitwear

山田きく代

We are separated by the Pacific Ocean, the 14-hours time difference . But my tru-knit arrived very quickly to Japan.

This machine is working very smoothly so my first tru-knit socks are perfect . It’s a great products !! I love it!

Thank you !

Jo Chester

Wow! Just wow! My Tru Knit arrived into Australia quickly, packed exceptionally well.

Straight out of the box this machine is a dream to use. Simple design with a few welcome additions and tweaks – and you can tell it’s been designed by a person who knows exactly what a perfect CSM should be! They’ve nailed it!

Superb machine!!

Highly recommend!!!

Ellen Hartstack

I’ve been a hand knitter (and other fiber related craft enthusiastic) for decades but the Tru-Knit is my first ever Circular Sock Machine. The machine has been expertly designed and clearly has design features from someone with an intimate knowledge of how CSMs should work and understands those “annoying” quirks of some of the other popular machines out there and has done her best to address them.

If you forced me to pick out the literal only flaw with the machine that I have is that the current row counter doesn’t auto shut off if unused and I have to remember to turn it off when I’m done cranking, which as my **only** extremely, extremely mild complain is seriously an incredible testament to how amazing this machine is and how well it functions. I have had this product for 3 months now and have cranked out over 20+ pairs of socks, mittens, hats, dolls, cat toys, coin purses and more!

I run a fiber mill and we are planning on using this machine in production to make socks and other items for our customers. Great product. Great price. Fantastic customer service. Would highly recommend!

L S

The tru-knit is an exceptional sock machine, with unparalleled customer service.

I have two other circular sock machines, both from modern makers. The tru-knit surpasses both. It is reliable, easy to use, and incorporates some really ingenious new features that makes using the machine simpler.

I love the different length slots on the ribber; it makes it very easy to pick out where you need to put the needles. The etching on the side of the cylinder to help you consistently set the right tension is genius.

More than anything, though, what makes the Tru-knit stand out is its superlative and exceptional customer service. Jamie stands behind her product and will help you troubleshoot any difficulty you might have. She literally includes her cell phone number with the Tru-knit and is very serious about responding to questions quickly and thoroughly. So far, i haven’t been able to stump her with any problem; her circular sock machine knowledge is extensive.

Any sock machine is an expensive purchase, but you can buy a Tru-knit with confidence. You will have the support you need to get your machine up and running. It’s an incredibly well-made, logical machine backed by excellent customer service and experience.

Judy Cherry

I’ve had my Tru-Knit since January. I admit that it’s a bit of an investment, BUT it is worth every penny! I am slowly working on building up my stash of cylinder sizes, but I’m very happy with what I have so far. Customer service is absolutely fabulous! Jamie is very quick to respond and can also get you going with your new machine. If you’re thinking about getting a circular sock knitting machine, this should be the one!

Lee Moeller

Love my machine! Received it earlier than scheduled and the customer service is outstanding! Jamie makes herself available to us to make sure we are successful crankers. Cannot be happier with this product and company. Thank you, Tru-Knit team💜

Renae Haddadin

I bought a tru -knit CSM based on the recommendation of friends who had owned otherCSM brands previously and said this is the best. All I know is that the Tru-knit is great! I have had success right away watching videos and making socks. I see other people who own other brands who are afraid to use their ribber. I’ve used mine and it is amazing. Support from the owners is crazy good. I send a text and I get an answer. Fantastic machine AND company.

Linda Carlson

I love my Tru-Knit, and I love the customer service from Jamie and Jeff. They mail out orders so fast, usually the same day they get my order. They are always friendly and helpful, and answer any questions quickly and thoroughly. They are happy to share their knowledge and want to help us knitters be successful.

My Tru-Knit machine makes me happy every time I use it. The ribbing is so smooth and almost never drops a stitch, except because of operator error.

It was a wonderful day in my life when I bought my Tru-Knit!

Mathilda Bohanon

This is the very best CSM you could ever get. I’ve had 5 different makes of vintage machines. Some I restored and some I had professonally restored. I have another make of new machine I loved until Jamie and Jeff with all kinds of input designed Tru-Knit. I got on the list and got mine. Up and running and after a few adjustments I was making socks faster than I could have imagined. The best feature to me is the ribber with an alternating slot pattern and the star of the machine,THE SILVER BULLET YARN GUIDE. No kidding…no dropped stitches. It opens the latches I don’t catch with my old eyes. No re adjusting all the time and like a good instrument it STAYS IN TUNE! It is happy knitting from coming out of the box. GET A TRU-KNIT AND CRANK ON!

Susanne Eichhorn

It was love at first sight. I have my TruKnit for a week and I love her. I watched the training videos on Sock TV and even as a beginner knitter I was able to knit right on. Absolutely wonderfull machine!!!

Lisa Witter

Our 4 yr old granddaughter said it best, “GRANDMA! Your new machine is beautiful. SO beautiful!” We then cranked our first of hopefully many socks (and grandma didn’t even say any bad words)! Coming from a family of engineers and architects, I can definitely appreciate the true beauty of this machine and the time and effort taken in its design and manufacture.

Sharon Wagner

I have had my Tru-Knit for a year now, Mrs. Fitz is the most reliable smooth knitting machine -period. I love my antique girls, but my Tru-Knit is my go to machine.

Jamie’s determination to make a superior machine, mission accomplished, has removed all fear and hesitation when sitting down to knit any project! The precision of this machine means that the only problems with knitting are the ones I create when I MAKE A MISTAKE!

Did I mention that Jamie & Jeff go above and beyond when it comes to customer service? They are quick with assistance for the smallest things, and the happiest folks I know!

I am totally and utterly satisfied with my Tru-Knit.

You could be too!

Cristina Saldana

I had been following Jamie’s how-to videos for a long time before I decided to purchase a used CSM, I learned most of the techniques from her while practicing on my Legare 47. When Jamie announced her Tru-Knit machine, I quickly ordered mine. I am at awe of how well this machine is made and the superb quality and functionality of each component. I love my Tru-Knit and I am thankful for the attention to detail, amazing customer service and the proactive approach to helping people learn how to use their machine and troubleshoot.

Jennifer Hamlin-Navias

The Tru-Knit is so well designed. Clearly it was designed by someone who is very familiar with Circular Sock Machines and who knows what features to include. If you get one you will love it.

Donna McFarland

I waited to order my Tru Knit for a few reviews. I should not have done that! It’s wonderful! So easy to use, easy set up, easy adjustments and light weight. I went to my first crank-in with it and set it up. All of my settings were still set and I started knitting immediately. I don’t have dropped stitches any more, my tension is perfect and ribbing is now a joy. This is my third machine and I love it!

Jan Krentz

I have been knitting on my Tru-Knit for nearly a year (2023 to early 2024). It is a beautifully designed and engineered machine! When knitting, the cranking is smooth and the Silver bullet yarn carrier rarely drop stitches! Changing cylinders and ribber dials is simple and straightforward. The Tru-Knit is a lighter-weight machine (as compared to older CSMs) and I can easily take it to CSM gatherings / Crank-ins. The new manufacturing process makes purchasing additional cylinders and ribber dials easy. The customized engraved tool set is a very nice touch. Many Tru-Knit owners have named their new machines….. mine is ‘Black Beauty’! I love my Tru-Knit!

Martha Meyer

I’m writing this review of my TruKnit CSM to let everyone know what a fabulous machine it is! I’ve had an antique machine for several years and like it but the TruKnit is many steps above it! I knitted socks with it right out of the box. Perfect socks for me! I’ve not had any questions about the machine but I wouldn’t hesitate to contact customer service if I did. I’ve heard from others that it’s top notch and I’m not surprised! It a wonderful machine and I’m looking forward to knitting many more thing with it in the future!

Cro-Magnon Socks

I’ve been using my Tru-Knit for 2 months and I love it. There are so many thoughtful aspects of the design that I appreciate every time I make a pair of socks. The machine is forgiving if knots slip by my notice, the knitting is always even, and once I’m sure my tension is even 360° around the cylinder, the ribber rarely drops a stitch. As with every single machine, my T-K has its little ways, but once I learned how it works best, it’s consistent and totally dependable. Like its creator(s), it’s a smarty pants. 😀

Susan Davis

This machine is AWESOME!!! It is evident that Jamie has taken feedback (and her own experience) of what works and what doesn’t in developing this machine! Between her and Jeff’s masterminds and the “guys” at the machine shop they have developed a wonderful machine. Her customer service is also unmatched! Thanks Jamie and team!!!

pamela fromenthal

Love my machine. It is a joy to knit with.

Dorinda Balanecki

Amazing machine. So precise and easy to use makes it so fun to use. The customer service is just as amazing as the machine. Everything about this machine is pure joy! Thank you to the TRU-KNIT team!

cindy fitch

I am reviewing the Tru Knit based on my experience with 2 machines I have previously owned and used to make many a pair of socks. The performance of the ribber makes ribbing very easy and no dropped stitches.The design of the slots on ribber dial is an innovative improvement for placement of ribber needles. I like how the cylinders are marked for adjusting the stitch length. There are many improvements on this machine from the previous machines I have used overall.The function of the ribber for me is what I am most pleased with. I recommended the Tru Knit if your looking to purchase a CSM.

Jennie Woolworth

I just got my new Tru Knit and am killing it making socks. For 10 years I’ve worked on 100 year old machines. This Tru knit is designed to never drop a stitch. Unbelievable my hobby is now complete. If you buy one you’ll never be sorry.

compared to

BiBi’s Atelier

I own several antique Circular Sock Knitting machines and at first I was hesitant to consider the Tru-Knit due to the price. I watched Jamie use her Tru-Knit and over time became convinced that it was worth the money! Boy, am I ever glad I made the decision to buy this machine. It has really upped my sock making game! If you’re serious about making socks this is the machine for you. It has every feature you could imagine plus some you don’t even realize you need – until you use it! The other super plus is the level of customer serve that Jamie and Jeff provide. Jamie makes herself available to answer your questions by phone! Then there’s socktv where Jamie teaches you how to knit just about anything you can imagine knitting on a circular knitting machine. The Tru-Knit is a great product, created by great people!

Melanie Coyne

My order was shipped extremely fast, website easy to use and as always Jamie was extremely responsive, friendly and helpful!!!

Sue Vunesky

I have used several antique and new sock machines. The Tru-Knit is by far the most advanced and easiest to use. Ribbing on the Tru-Knit is a dream come true!!!

Cindy Barkhuizen

Beautiful machine! Knits smoothly and everything is so well finished. The ribber behaves and the long and short slits make it easy to choose the right slot. It is packed beautifully with a carry case that can be used again. It comes with extras, like your tools, a cone of yarn and needles in cute containers.

The customer service is OUTSTANDING!!

Sheila Graham

As all my fellow cranker know I have owned several different brands of CSM’s ie; Gerhardt, Auto knitter, Legare 47, a French Traveleurs, Creelman Money maker 2 and now a Tru Knit. Of all the ones I have owned, I still own the TruKnit and the Creelman Money Maker 2. These are considered by me to be 2 of the best machines of all owned. The TruKnit is my overall pick for several reasons. It is lightweight, it is precise, it is very easy to use and to learn on. Quite frankly, I always struggled with the ribber until my TruKnit arrived. Straight out of the box ribbing magic happened! No hula, no dropped stitches, no naughty language. The TruKnit was designed by a knitter for knitters! Since the arrival in September I have make over 100 pairs of ribbed socks! Thank you Jamie for all the work and thoughtfulness that went into making this beautiful machine.

Danita Gabbrants

The Tru-Knit csm is a great machine. I can see that a lot of thought went in to making this machine. The owners are very thorough in their decisions in making this what I fell is the best Csm on the market.

Diane Branham

I love this machine. It is so easy to use and I now use my ribber for every pair of socks, unlike when using my other machine. I dreaded using the ribber on that machine.

R Conner

Extremely well made and wonderful customer service! So glad I bought it!

Connie V

I have had my Tru-Knit for a year now. It is awesome! It ribs beautifully,never dropping a stitch. I own 6 machines of various ages and the Tru-Knit is my very favorite . Jamie has designed the best machine, gives the best customer service and her expertise is icing on the cake.

Linda Dossett

Lightweight, excellently updated and redesigned CSM. Easy to install, set up and use. Priced competitively with other new CSM machines. The best I have owned and used so far.

Jacqueline Urband

The best csm on the market, in my opinion, with great customer service and support!

lori gartner

The Tru-Knit and the CSM community has made me a much better sock knitter! The silver bullet functionality really works to help prevent dropped stitches. Within weeks of upgrading from an antique machine I am using my ribber and cranking out beautiful socks! Jamie is very responsive and super helpful. 5 star product with 5 star service.

Denise Frame Harlan

The Tru-Knit is the smoothest sock-knitting machine I’ve ever knit on. I own a Chambord, and I’ve taught people to many types of circular sock knitters. While I do not own a Tru-Knit, I tested one at crank-in, and I was deeply impressed with the stabiity and predictability of the machine while ribbing. This is an amazing design that resolves many foibles of other machines. It’s also lightweight– if I were buying a machine today, this would be my choice.

Mathilda Bohanon

I love my TruKnit CSM. It is my 2nd. Brand new one. Have had 8 vintage machines. The best part is the yarn carrier, Silver Bullet. When adjusted right, it opens closed needles. The ribber is super! The easiest to use of any I have knitted on.

Elaine Adkins

The Tru-knit has built in improvements that increase the likelihood of success from the beginning. Using the Tru-knit has been a great experience. My first CSM was printed and often was frustrating due to failures.

Toni Lipe

I love my new Tru-Knit CSM!!! Much easier to use than my previous CSM! The videos are so helpful. Customer Support is excellent!

Becky Bechthold

I replaced my antique AutoKnitter with a Tru-Knit. It was the best decision I ever made!! This machine takes all of the a guesswork out of using a sock knitting machine. It is very intuitive and easy to use. On the occasion I have needed support, Jamie and Jeff could not have been more helpful! 😍🤩

Joann Grubb

This machine is awesome. The silver bullet opens the latches perfectly. The ribber never drops a stitch. Jamie Mayfield is always available for any questions or problems you may have. I highly recommend this product and company.

Ann Meminger

Love, love, love my new Tru-Knit circular sock machine! I have owned other sock machine but nothing compares to the Tru-Knit. This machine is smooth, precise in its manufacture and beyond beautiful in its appearance! I’m so happy that I decided to order from Jamie & Jeff!

Anna Fricker

I love my TruKnit! It is quiet, smooth and so easy to crank.

The silver bullet yarn carrier is a work of art. When it is adjusted properly, the yarn carrier opens closed cylinder needle latches and avoids dropping stitches. This is truly a game changer.

Every time I sit down at my machine I am amazed at how easy it is to knit.

Ribbing is a joy! I used to struggle and hated ribbing. Now I rib every sock I make.

This machine is marvelous and gives me the confidence to try new techniques and patterns. I know I won’t be fighting the machine while trying to learn a new skill.

I can’t say enough about the customer service. If you have a question or a problem, just text Jamie Mayfield and she answers quickly and will work with you to help resolve the issue. Jamie is a gem!

Kathy Rickard

The Tru-Knit is TRUly excellent!! It is a precision instrument. Tru-Knit is thoughtfully (and brilliantly) designed and precision engineered. Jamie amalgamated the very best elements of several different styles of CSM (both antique and modern) and thoughtfully innovated to produce this superb machine.

I struggled with ribbing on my antique machines but was able to use the Tru-Knit CSM to rib flawlessly as soon as it arrived! The machine comes sturdily packaged, tested (with sock, cone of yarn and “recipe” for the second sock of the pair) and ready to get cranking. Jamie and Jeff’s customer service is impeccable. I highly recommend the Tru-Knit to anyone and everyone. It’s “ the bees’ knees” Tru-Knit is truly terrific!

Arlene Hamilton

My Tru-Knit is a beautiful machine to interact with. I’ve knitted on 3 other machines and the Tru-Knit out performs them all! I knit faster, smoother and with no issues each time I use it. It’s easy to put together and take apart. The attention to detail of parts is over the top. It’s smooth and like knitting with butter (if that was possible). I think it’s a game changer in the world of CSM. Don’t settle, buy a Tru-Knit.

Judy P

I love my tru-knit. I keep the silver bullet adjusted so it opens the latches as it knits.

Lightweight and easy to use. Great customer service.

Sandee Plocharczyk

I absolutely love the Tru-knit sock knitting machine. It’s so easy to crank…smooth. The bullet yarn feeder is fabulous especially doing heels and toes. This machine just glides! I haven’t dropped a rib stitch and have knitted tons of socks. I just can’t say enough good thing about this machine. It’s AWESOME!!

Donna S

This is my 3rd machine, but i still needed a few hours practice to get to know her…to get the feel of it all…and now here I am making beautifully ribbed socks with confidence. The magic bullet works wonderfully. The markings on the cyclinder for adjusting tension is genius. Watch all the videos on the website – they are a wonderful resource and really help you to understand your machine. Customer service is stellar …Jaime and the rest of the community are so supportive . So very happy to be a Tru-Knit owner!

Deborah Knight

The precision manufacturing of the Tru-Knit makes it a joy to use. Thank you, Jamie! Who knew knitting socks could be so much fun! ❤️

Celeste A

Truknit is a well thought out top notch machine with spectacular customer service. Highly recommend and worth every penny.

Judy A

Knits and ribs beautifully, love the help videos

Lea Stinson

Dream machine!

Linda Randolph

I’m so glad I purchased my Tru-knit, I love the ribber and the ease of adjusting it. The yarn guide is a great idea not only in looks but for changing from one yarn to another

The lock that they put on the machine to prevent someone from cranking the handle and messing up a project is a fantastic update.

I feel this machine has so many update and improvements for future CSM owners and is still keeping with the original design of CSM machines.

Adrienne Rieck

The Tru-Knit circular sock machine is amazing. It’s extremely user-friendly, super easy to crank, and using the ribber is a DREAM. Oh, and customer service, should you ever need it, is phenomenal. This is the machine that you want. For real. 🙂

Paula Walters

I’ve owned my Tru-Knit for a year, it’s a fantastic machine and a real joy to knit on. The workmanship is top notch, everything is precision machined resulting in a very smooth operation. This machine even makes it easy to knit cables. Customer support from Jamie and Jeff is second to none, they really care about making their customers happy with their products. Highly recommend!!

Rosalyn Keys

Amazing customer service and a fantastic machine! Runs smooth and efficiently (as is no dropped stitches) Package came with everything I needed to get started.

David Huelster

The Tru-Knit csm is a truly great knitting machine. I have owned and used 4 different csms, all purchased new. Tru-knit is the only one where everything fit together perfectly, no slop anywhere. Tru-Knit is the only one which lacks hula. That is because it is made so well. It knits and ribs easily. It is also the lightest csm I have owned but feels so very solid. It is so very portable.

Judy Rouse

So pleased with my new Tru Knit. This is my second circular sock machine and is a noticeable improvement. It is a joy to use.

Julie Pulkrabek

I enjoyed my first Tru-knit so much that I recently bought a second one. These machines run so smoothly compared to my first machine. I recently conquered my ribber fear (with the help of Jamie’s husband, Jeff) and am now making ribbed socks. It is amazing to use a ribber that does not drop stitches and that I do not have to adjust every time I remove it. The Tru-knit is made so that all of the settings stay the same until I change them. What a treat!! Jamie’s knowledge of CSKMs and the quality manufacturer she chose to work with made these amazing machines. Thanks so much Jamie Mayfield!!

L Sykes

I absolutely love this machine. I’ve owned another major brand and was never able to make two matching socks in a row unless it DID NOT include the ribber. This machine was sold in order to buy the Tru-Knit. I am also very happy with the weekly shows with demonstrations on how to avoid issues, gives you helpful hints, plus get a variety of patterns to try that you will be successful with. The support is consistent and there are no stupid questions 👍🏽 I highly recommend the machine and the folks behind it. Thank you Jamie and Jeff for taking the time to make us happy.

Connie Reeves

What an exceptional machine. I own a couple vintage Gearharts and a Erlbacher but my Tru-Knit has become my primary machine for making things. Jamie and her team worked to take the best features that you find in many machines and incorporate them into a unique and effective machine. I’ve owned my machine since about April of 2023. You will not be disappointed.

Jennifer Bremer

The Tru-Knit is truly the next generation of circular knitting machines. I appreciate all the innovations that have been integrated into this machine based on many collective years of troubleshooting, teaching, learning and listening.

Some of my favorite features include….

The gauge marks on the cylinders, the easily adjusted and lockdown ribber stop, the ability to lock the handle when not in use, the infallible yarn guide (aka. the silver bullet), the large/small alternating ribber slots, and so many other features makes this my absolute favorite machine and the one I go to as my production workhorse.

Thanks to Jamie Mayfield and her team for putting so much into making the Tru-Knit Tru-Joy to use. The quality of the machining possibly makes this the first out-of-the-box set-up-and-knit machine. I love the Tru-Knit!

Pisky Cove

The machine is fantastic! It has the best features of my antique machines improved as only a fellow sock cranker could. The after sales is second to none, even when the mistake is your own stupidity!! 🫣

Highly recommend the Tru-knit as both a beginner and beyond machine, you can tell has been designed by someone who both loves and lives this style of knitting, engineered to the highest standards, supported by personal contact and a plethora of teaching videos.

Only downside is you will have to get your name on a list to get one BUT good things come to those that wait! 🥰

The Tru-Knit is the best!

Consistency is key for me, especially when it comes to crafting socks. With the Tru-Knit and Tru-Gauge by my side, achieving that consistency is not only achievable but also effortless. The yarn carrier, or what I affectionately call the “silver bullet,” is a masterpiece in both design and functionality. It has bailed me out countless times, deftly catching and reopening cylinder needles that had sneakily closed shut.

Having owned and operated six different CSM machines in my time, I can confidently say that the Tru-Knit reigns supreme. Its reliability and ease of use are paramount for my wife and me, as we produce and sell socks (along with other knit items). In fact, we’ve doubled down on our investment with two Tru-Knits, and the results have been nothing short of awesome.

And let’s not forget Jamie—hands down, the epitome of exceptional customer service.

Product Updates From Jamie:

- February 2024 Update

by Jamie MayfieldWe have been busy assembling and shipping Tru-Knit Circular Knitting Machines. We have shipped 201 machines and are prepping more as I type. We just returned from PIGs in Ankeny, IA. It was exciting to see friends and so many Tru-Knits at the crank-in. Our site has mainly been a place for me to post product updates, but we are adding new content all the time. Tru-Knit User Guides How-To Videos Tru-Knit Product Page Coming soon is our online store.

by Jamie MayfieldWe have been busy assembling and shipping Tru-Knit Circular Knitting Machines. We have shipped 201 machines and are prepping more as I type. We just returned from PIGs in Ankeny, IA. It was exciting to see friends and so many Tru-Knits at the crank-in. Our site has mainly been a place for me to post product updates, but we are adding new content all the time. Tru-Knit User Guides How-To Videos Tru-Knit Product Page Coming soon is our online store.

Read Past Product Updates and News from Jamie.

Sign up our Newsletter